In today’s tech-savvy manufacturing industry, precision is truly everything. Whether it’s a medical device, fuel system or aerospace accessory, the tiniest of leaks can lead to disastrous recalls and product failures.

In the past, companies would rely on leak testing that involved physical prototypes and processes that were accurate—albeit expensive and time-consuming. This is now beginning to change as a new, digital revolution known as digital twin technology is altering this type of workflow for countless businesses around the world.

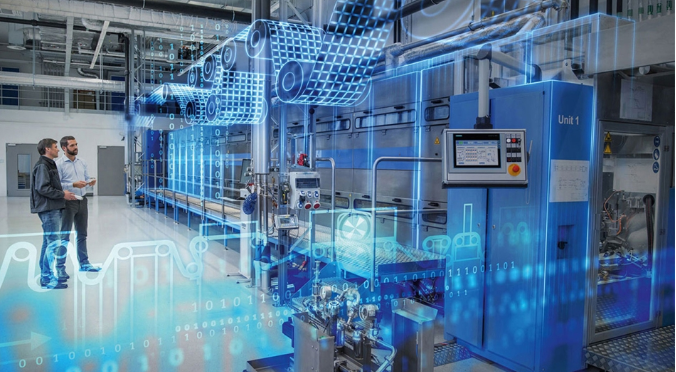

Digital twins offer virtual models that mimic physical system behavior in real time, and when paired with advanced leak test systems, these simulations give engineers and manufacturing teams the ability to detect vulnerabilities, predict future performance, and optimize product designs well before products are finalized.

So, check out the below sections to learn more about how digital twin technology is leading to more sustainable, faster and more precise product validations!

What Exactly Is Digital Twin Technology In Leak Test Systems?

Digital twin technology involves so much more than simply a 3D model, because it’s a data-driven, dynamic replica of a real product system that offers a direct reflection of the materials, physical characteristics and environmental interactions.

In terms of leak testing, digital twins are utilized to simulate temperature, pressure and fluid dynamics that’ll ultimately interact together within the sealed system. Engineers can now model how potential leaks might happen, where a product’s weak points could potentially develop, and how certain components and parts might perform under all sorts of different real-world conditions.

By connecting this type of tech-savvy simulation software with real leak testing data, digital twins can create a comprehensive feedback loop between both the virtual and physical testing. This means that the technology continuously improves upon itself and recommends maintenance when necessary.

Reducing Costs & Time In Product Development

Although conventional leak testing systems do a great job at performing repetitive tasks and making modifications until specific results are met, these changes can often cost businesses a lot in materials, labor and time.

With digital twin technology, manufacturing teams can now run countless virtual tests featuring a seemingly endless number of scenarios—all within a matter of a few hours. So instead of relying on many different physical tests, engineers can simulate the effects of potential design changes like seal geometry, wall thickness and material composition.

This digital approach can significantly reduce physical waste and rework, which ultimately leads to lower development costs and faster product launches. And in industries like the aerospace and automotive sectors, digital twins often cut down validation cycles by upwards of 30-50%.

Utilizing Real-Time Data To Enhance Leak Testing Accuracy

What’s really intriguing about digital twins is that they’re fully connected to live data streams, which essentially means that today’s leak test systems are equipped with IoT connectivity, state-of-the-art sensors, and analytics platforms that can feed valuable data into your virtual models.

This unparalleled synchronization allows your digital twin system to evolve alongside your product development through continuously learning from environmental conditions, ongoing test results and production variables. Engineering teams can now more easily fine-tune their simulations in ways that mirror real-world testing behavior—which then typically leads to more precise results.

And over long periods of time, this tech combination develops into a self-improving validation system that improved quality control and allows for more predictive leak detection in future production runs.

Supporting Compliance & Sustainability

Beyond leak testing precision and speed, digital twin technology is also closely aligned with regulatory compliance and sustainability goals.

By minimizing physical prototypes, manufacturing teams can subsequently reduce energy consumption and waste. Virtual leak test simulations also help businesses to meet increasingly stricter environmental and safety standards long before production even begins.

Leak integrity just so happens to be crucial for certain sectors like medical device manufacturing, and digital twins are now helping to provide data-backed, traceable validation that can streamline regulatory approvals and certifications.

Predictive Leak Test Systems Are The Future

As digital twin technology naturally gets more integrated with leak testing workflows, the next tech-driven step will likely be predictive validation using forecast-capable machine learning to warn companies of how, when and where failures might happen.

There’s no telling just how far predictive validation can go in terms of transforming product maintenance, because manufacturing systems will now essentially be able to speak for themselves and alert professionals of proactive repairs that’ll avoid downtime.

AI-driven leak test systems are now becoming more of a possibility than ever, which means that autonomous testing environments will be able to refine themselves over and over again by utilizing both simulated and historical data.

Digital Twin Technology Is Bridging The Gap Between Leak Test System Simulations & Reality

Leak test systems have long been reliable, precise and protective; however, with digital twin technology, there’s officially a new era of innovation that’s revolutionizing how manufacturing teams go about their daily routines.

By combining virtual simulations with real-world data, businesses of all types can be faster with their product validations—all while also reducing waste and ensuring pinpoint accuracy.

And as countless industries continue to embrace the ongoing digital transformation associated with Industry 4.0 trends, the connections between virtual and physical testing will only grow deeper!