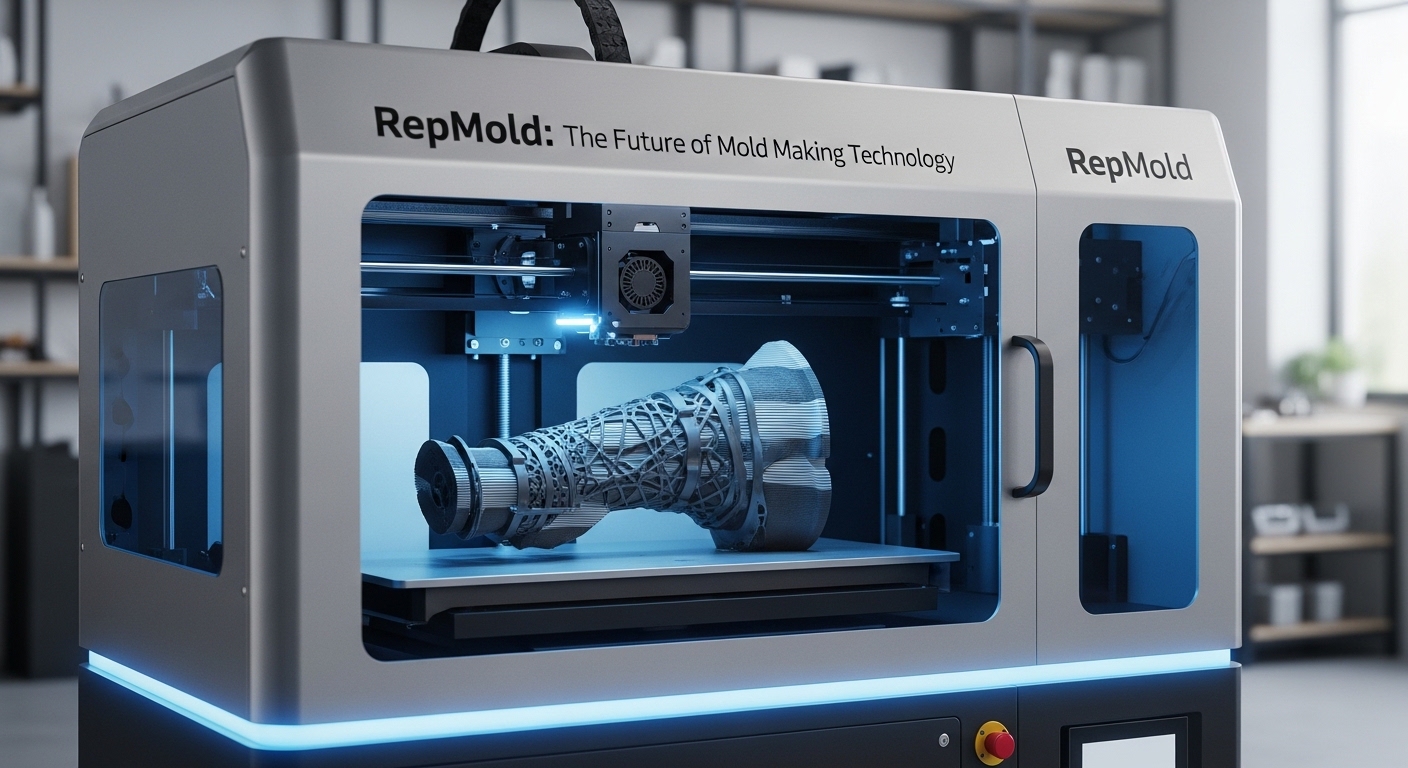

Mold making has long been a cornerstone of manufacturing, shaping everything from automotive parts to intricate toys. As industries evolve, so do the technologies that support them. Enter RepMold—a game-changing innovation that’s setting new standards in efficiency and precision. Imagine a process that not only speeds up production but also enhances accuracy while reducing costs. This is where RepMold steps in, transforming how molds are created and used across various sectors. Whether you’re an industry veteran or just curious about modern manufacturing trends, offers insights into the future of mold technology you won’t want to miss.

How RepMold is revolutionizing the mold making industry

RepMold is changing the landscape of mold making. Its innovative approach allows for rapid production without sacrificing quality. Traditional methods often require extensive lead times and resources. RepMold cuts through this inefficiency.

With its advanced technology, manufacturers can create complex molds in a fraction of the time. This agility enables quicker response to market demands and customization options that were previously unimaginable.

The precision offered by RepMold reduces material waste significantly. Every element is optimized for performance, leading to cost savings across the board.

Additionally, RepMold encourages sustainability within the industry. By minimizing energy consumption during production, it aligns with modern eco-friendly initiatives.

Companies adopting RepMold are experiencing an increase in productivity alongside enhanced creativity in design processes. The future looks bright as more businesses recognize these advantages and pivot towards this cutting-edge solution.

The science behind RepMold: Understanding the technology

RepMold harnesses cutting-edge materials and advanced techniques to create high-quality molds. At its core, this technology uses a unique polymer blend that is both durable and flexible. This combination allows for intricate designs with precise details.

The process involves digital modeling, where CAD software plays a critical role in mold creation. Once the design is finalized, RepMold employs additive manufacturing methods to produce molds layer by layer. This not only speeds up production but also reduces waste significantly.

Another fascinating aspect of RepMold is its ability to adapt quickly to changes in design specifications. Traditional methods often require extensive rework; however, with RepMold’s agile approach, revisions can be made swiftly without compromising quality.

Furthermore, the temperature resistance of materials ensures they perform consistently under various conditions, making them ideal across multiple industries—from automotive to consumer goods.

Comparing traditional mold making methods vs RepMold

Traditional mold making methods often involve labor-intensive processes and lengthy lead times. Craftsmen meticulously carve molds from metal or other materials, which can be costly and time-consuming.

RepMold changes the game by utilizing advanced technologies like 3D printing and smart material applications. This allows for rapid prototyping, significantly reducing production timelines.

While conventional techniques may produce durable molds, they come with constraints in design flexibility. embraces intricate designs that were once deemed impossible to achieve with traditional methods.

Moreover, traditional molding can result in higher waste levels due to excess material removal during fabrication. In contrast, RepMold maximizes efficiency through additive manufacturing principles that build layers precisely as needed.

The adaptability of RepMold technology also means manufacturers can easily adjust their designs without starting from scratch—streamlining the entire development process while minimizing costs associated with retooling.

Case studies and success stories of companies using RepMold

Several companies have embraced RepMold, experiencing remarkable transformations in their production processes. One notable case is a leading automotive manufacturer that reduced its mold lead time by 50%. With faster turnaround, they could respond swiftly to market demands.

Another success story comes from a consumer electronics firm. By utilizing technology, they achieved greater design flexibility and precision. This allowed them to innovate rapidly and launch new products ahead of competitors.

A small startup in the toy industry also benefited significantly from adopting . With lower initial costs and high-quality output, they scaled their operations quickly without compromising on quality.

These examples illustrate how diverse industries are harnessing the power of . Each company found unique advantages tailored to their specific needs in an ever-evolving marketplace.

Future developments and advancements in RepMold technology

The future of RepMold technology is bright and full of potential. As the demand for efficient manufacturing processes grows, innovations are on the horizon.

One exciting area is the integration of artificial intelligence. AI can enhance precision in mold designs, allowing for greater customization and faster iterations. This means quicker turnarounds and more tailored products.

Another development involves sustainable materials. The industry is shifting towards eco-friendly options that reduce environmental impact without sacrificing quality. RepMold could lead this change, creating molds from biodegradable substances.

3D printing advancements also promise to play a crucial role in RepMold’s evolution. Faster printing technologies will enable even more complex designs, pushing boundaries beyond traditional capabilities.

As these developments unfold, they may redefine how industries approach mold making—creating opportunities that were previously unimaginable while maintaining high standards of efficiency and sustainability.

Conclusion: The impact of RepMold on the manufacturing industry

The emergence of RepMold is reshaping the landscape of the manufacturing industry. Its innovative approach streamlines mold making processes, offering unparalleled speed and efficiency. Companies embracing RepMold technology are witnessing significant reductions in production timelines and costs.

This advancement not only enhances productivity but also promotes sustainable practices by minimizing waste. As businesses adapt to these new methods, they position themselves at the forefront of their industries.

With ongoing developments expected in RepMold technology, it’s clear that its influence will continue to grow. The future looks promising for manufacturers willing to integrate this cutting-edge solution into their operations. Embracing RepMold could very well be a game-changer for those seeking competitive advantages in an ever-evolving market.