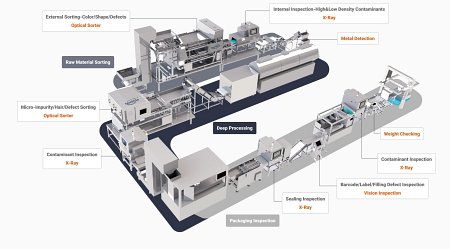

Food inline x ray technology helps companies identify unwanted substances in food and packaged goods. Inline x-ray machines use advanced imaging and AI to find foreign objects that could harm consumers. RaymanTech x-ray inspection systems combine multi-modal detection and smart algorithms to improve contaminant detection. These systems make food safer and protect brand reputation.

Food Inline X-Ray: How Detection Works

Principles of Inline X-Ray Machines

Inline x-ray machines for food operate based on several scientific principles. These systems generate a controlled x-ray beam that passes through food products moving on a conveyor. Different materials inside the product absorb x-rays at different rates. Dense materials, such as metal or glass, absorb more x-rays than the surrounding food. This difference in absorption allows the system to create detailed grayscale images that highlight variations in density.

The following table summarizes the core principles behind food inline x ray technology:

| Principle | Description |

| X-ray Generation | A controlled x-ray beam passes through the product on the conveyor |

| Differential Absorption | Dense contaminants absorb more x-rays than surrounding product |

| Image Capture | Detectors create a detailed grayscale image showing density variations |

| AI Analysis | Advanced algorithms identify anomalies and contaminants in real-time |

| Automatic Rejection | Contaminated products are diverted from the production line |

Dense contaminants, such as glass and metal, appear brighter on x-ray images because they absorb more energy. Plastics and other low-density materials absorb less, making them less visible but still detectable with advanced systems. The absorption characteristics depend on the material’s density and atomic mass. This principle helps inline x-ray machines detect contaminants that differ from the food product itself.

Imaging and Contaminant Detection

Modern food inline x ray systems use advanced imaging technologies to improve detection. Photon-counting technology plays a key role in identifying contaminants. This technology reduces false rejects and makes rework easier, which increases the effectiveness of contaminant detection. Some systems, like RaymanTech food x-ray inspection system, use dual energy photon-counting combined with sophisticated image analysis software. These features allow the machines to distinguish between different types of contaminants and food products.

- Photon-counting technology enhances image clarity and accuracy.

- Dual energy imaging helps separate contaminants from food, even when densities are similar.

- These systems support quality assurance across many industries.

RaymanTech x-ray inspection systems integrate visible light and AI-driven algorithms to further improve detection. The AI analyzes images in real time, identifying anomalies and classifying defects. This approach ensures that the system can detect contaminants such as metal, glass, plastics, and even bone fragments.

Real-Time Analysis and Automation

Inline x-ray machines provide real-time analysis and automation, which strengthens food safety and quality control. AI algorithms analyze large datasets, learning to recognize patterns and classify defects. These systems adapt to new contaminants and refine their detection capabilities using production data. Deep learning reduces false positives and increases reliability.

Automated x-ray inspection systems alert operators to contaminants and help ensure compliance with food safety standards. They reduce the burden on employees and minimize human error. Automated systems can detect foreign objects like stones and plastics within food, improving data capture and storage for quality assurance.

RaymanTech’s x-ray inspection systems use intelligent algorithms that learn from production conditions. The machines flag defects that traditional methods might miss. Automation ensures that contaminated products are removed from the production line quickly, protecting consumers and maintaining high standards for food quality.

Types of Contaminants Detected

Inline x-ray machines play a vital role in food safety by identifying a wide range of contaminants. RaymanTech systems use advanced imaging and AI to detect contaminants in bulk products, packaged goods, and processed foods. These machines help companies maintain high standards of quality and protect consumers from harmful substances.

Metal, Glass, and Stones

RaymanTech food inline x ray systems excel at finding dense contaminants. The RXI BHD Series specializes in bulk product inspection, using x-ray technology to spot metals, glass, stones, and ceramics. These contaminants often enter food during processing or packaging. The following table shows common types detected by RaymanTech systems:

| Contaminant Type | Description |

| Metal | Various metals detected |

| Glass | Includes shards and fragments |

| Ceramic | Various ceramic materials |

| Stone | Different types of stones |

| Hard Plastic | Dense plastic materials |

| Bone | Animal bone fragments |

| Dense Rubber | Thick rubber materials |

| Other Dense Impurities | Any other dense contaminants |

Inline x-ray machines use differential absorption to highlight these materials. Glass shards and metal pieces appear brighter on x-ray images, making them easier to identify and remove. This process helps companies deliver safe food to consumers.

Plastics, Paper, and Organic Materials

Not all contaminants are dense. Some, like plastics and paper, have low density and can be difficult to detect. RaymanTech’s Dual Energy Series uses dual-energy x-ray technology to improve detection of these materials. This technology analyzes two energy levels, increasing sensitivity for low-density contaminants.

| Detection Technology | Description |

| Dual-energy X-ray technology | Utilizes two energy spectra for high sensitivity in detecting organic materials and contaminants. |

| Identification capabilities | Effectively detects low-density contaminants such as cartilage, rubber, and plastic in food products. |

| Application | Suitable for various food types including salads, mixed nuts, and cereals, enhancing food safety. |

The Dual Energy Series identifies plastics, rubber, and even organic materials like cartilage. This capability is important for foods such as salads, cereals, and mixed nuts. Inline x-ray machines help companies detect contaminants that traditional metal detectors might miss.

Tip: Dual-energy x-ray inspection increases food safety by finding hidden contaminants in products with mixed ingredients.

Bone Fragments and Internal Defects

Bone fragments and internal defects pose risks in meat, poultry, and fish products. RaymanTech systems generate detailed internal images using x-ray beams. These images reveal foreign objects and structural defects without damaging the food.

- X-ray inspection systems create clear images of meat and poultry.

- They identify bone fragments and inconsistencies inside products.

- These machines detect hidden contaminants, ensuring product integrity.

A beef processor saw a 20% drop in customer complaints after using x-ray inspection. The system helped workers separate bones from meat, improving quality and safety. Inline x-ray machines also find internal defects, such as air pockets or broken pieces, that could affect product quality.

RaymanTech’s Dual Energy Series provides precise detection for bone fragments and fat content. This technology supports processors in meeting industry standards and delivering safe food to consumers.

Note: Inline x-ray machines help companies detect contaminants and maintain high levels of quality in every batch.

Inline X-Ray Inspection Process

Product Entry and Positioning

Food inline x ray systems begin with product entry. Workers place food items or packaged goods onto a conveyor belt. Inline x-ray machines position each item for optimal scanning. The system uses sensors to align products, ensuring consistent product inspection. This step reduces blind spots and improves the accuracy of detection. RaymanTech designs its machines to handle bulk products, packaged goods, and containers of different shapes and sizes. Proper positioning helps the system detect contaminants in every batch.

Scanning and Image Analysis

Once positioned, the x-ray beam scans each product. Inline x-ray machines use flat panel detectors to capture detailed images. These detectors highlight density differences, making it easier to detect contaminants such as stones, bones, or plastic shards. The system uses advanced image processing to scan for defects and foreign objects. RaymanTech’s technology measures chemical composition, identifies bruising, and classifies seeds. It also detects adulteration, ripeness, and freshness in fruits and vegetables. The following table summarizes key image analysis techniques:

| Technique | Description |

| Inline X-Ray Machines | Integrated into production lines for product inspection and contaminant detection. |

| X-Ray Detection | Uses flat panel detectors to identify stones, bones, or plastic shards in food products. |

| Image Processing | Automatically scans processed images for defects or contaminants, supporting quality control. |

Automated analysis ensures that every product receives thorough inspection. The system flags anomalies and sends alerts to operators when it detects contaminants.

Automated Rejection and Food Safety Compliance

After detection, the system activates automated rejection. Inline x-ray machines use mechanical arms or air jets to remove contaminated products from the line. This process protects consumers and maintains high quality standards. RaymanTech’s systems use AI to interpret data from multiple sources, updating operators about regulatory changes and potential risks. Automated rejection supports compliance with food safety regulations by enabling continuous monitoring and verification of food safety plans. Companies like Tyson Foods and IBM use AI-powered systems to track hygiene and traceability in real time. RaymanTech’s approach ensures that compliance is proactive, preventing issues before they affect production.

Tip: Automated rejection reduces human error and streamlines quality control, helping companies meet industry standards and deliver safe food to consumers.

Advantages of Inline X-Ray Machines

Accuracy in Contaminant Detection

Inline x-ray machines offer high accuracy in product inspection. These systems detect a wide range of contaminants, including metal, glass, and non-metallic objects. Unlike traditional metal detectors, x-ray technology identifies foreign materials based on density differences. This method allows detection of contaminants as small as 0.5mm. Inline x-ray machines work effectively with various packaging types, such as metal cans and foil pouches. They also reduce the risk of product recalls by catching hidden hazards before products reach consumers.

- X-ray machines can find glass, rubber, and dense plastics that metal detectors often miss.

- Metal detectors struggle with metallized packaging and wet or salty foods, but x-ray systems maintain accuracy in these situations.

- Food manufacturers rely on x-ray systems for comprehensive product inspection and improved safety.

Versatility Over Metal Detectors

Inline x-ray machines provide greater versatility in product inspection compared to metal detectors. X-ray systems assess the density of items, making it possible to identify contaminants like glass shards in jams or stone fragments in grains. These machines support food safety for packaged goods, ready meals, and canned products. Inline x-ray machines also excel at detecting bones in meat and poultry, which metal detectors cannot find. This versatility helps companies maintain high standards of quality control across different food types.

- X-ray systems detect non-metallic contaminants in a variety of foods.

- They ensure thorough product inspection for complex packaging and mixed ingredients.

- Inline x-ray machines help prevent product recalls by identifying hidden risks.

Reliability for Food Safety

RaymanTech inline x-ray machines deliver reliable food safety through advanced features and design. The modular structure allows easy maintenance and cleaning. Operators benefit from user-friendly controls and remote service options. Regular calibration and software updates keep the system accurate. RaymanTech machines inspect raw materials, processing stages, and final products, ensuring complete safety checks. AI-powered image processing enhances contaminant detection and supports compliance with industry standards.

| Feature | Description |

| Contaminant Detection | Finds metal, glass, and non-metallic impurities |

| Whole-Chain Inspection | Checks raw materials, processing, and final products |

| AI-Powered Image Processing | Uses advanced algorithms for accurate detection |

| Compliance with Safety Standards | Meets industry regulations for reliable food safety inspections |

Inline x-ray machines help companies avoid product recalls and protect brand reputation. These systems support consistent product inspection and quality control, making them essential tools in the food industry.

Impact on Food Safety and Quality Control

Reducing Risks and Ensuring Safety

Inline x-ray machines play a key role in reducing risks in food production. These systems add a second layer of protection against contaminants that metal detectors may miss. FreshHarvest installed FA-XIS X-Ray Systems on its busiest production lines. The combination of x-ray and metal detection creates a strong defense against raw ingredient risks and non-metallic contaminants. Food manufacturers use this approach to keep harmful objects out of finished products.

- Inline x-ray machines identify small contaminants before they reach consumers.

- They work with metal detectors to provide complete product inspection.

- The systems help prevent recalls and protect consumer health.

Food safety improves when companies use advanced x-ray technology. The machines catch issues early, which keeps food safe and maintains high standards.

Meeting Industry Standards

Food companies must meet strict industry standards for product inspection and safety. X-ray inspection systems help manufacturers comply with global regulations. The following table shows important standards that guide food safety and quality control:

| Standard | Description |

| BRC | Covers food safety management and product integrity |

| IFS | Ensures product quality and safety through detailed auditing |

| SQF | Provides a rigorous, consistent approach to food safety management |

| FSSC 22000 | Incorporates ISO-based food safety principles for a global framework |

X-ray inspection supports compliance with these standards. Companies use these systems to document quality control and prove that their products meet safety requirements.

Enhancing Brand Reputation

Advanced x-ray inspection systems help food manufacturers build a strong brand reputation. These systems improve product quality and operational efficiency. Companies detect contaminants and maintain compliance with safety regulations. Consumers trust brands that deliver safe food and high-quality products. A positive brand image grows when companies invest in reliable product inspection and quality control.

- Enhanced detection of contaminants reduces customer complaints.

- Quality checks lower the risk of recalls and protect brand value.

- Improved traceability and lower maintenance costs increase productivity.

Food companies that use x-ray inspection systems show their commitment to safety and quality. This approach helps them stand out in a competitive market.

RaymanTech X-Ray Inspection Systems set a new standard for food safety and quality control. These machines use advanced AI and dual-energy X-ray technology to detect a wide range of contaminants and measure fat content accurately. Key benefits include:

- Enhanced detection of metal, glass, and plastic hazards

- Improved production efficiency and reduced waste

- Comprehensive protection throughout the production process

| Key Aspect | Description |

| Foreign Object Detection | Ensures consumer safety by finding contaminants like metal and glass |

| Real-time Inspection | Supports continuous monitoring and minimizes production delays |

| Compliance with Standards | Meets ISO, HACCP, and FSMA guidelines for regulatory approval |

Modern x-ray inspection helps companies maintain compliance, protect their brand, and deliver safe products to consumers.

FAQ

How does inline x-ray inspection improve food safety?

Inline x-ray inspection finds contaminants like metal, glass, and bone fragments. The system removes unsafe products before packaging. This process helps companies deliver safer food to consumers.

Can x-ray machines detect low-density materials?

Yes. Advanced x-ray systems, such as RaymanTech, use dual energy technology. These machines identify low-density materials like plastics and paper, which traditional metal detectors often miss.

What types of food products can be inspected?

RaymanTech x-ray inspection systems scan bulk items, packaged goods, and beverages. The technology works with meat, poultry, fish, grains, and ready meals. The food industry relies on these systems for comprehensive quality control.

Tip: Regular calibration keeps x-ray machines accurate and reliable.

Are inline x-ray machines easy to maintain?

Operators find RaymanTech machines user-friendly. Modular designs allow quick cleaning and maintenance. Remote service options help reduce downtime and keep production lines running smoothly.

Do x-ray inspection systems meet regulatory standards?

Manufacturers design x-ray inspection systems to comply with global food safety standards. These systems help companies meet BRC, IFS, SQF, and FSSC 22000 requirements.

| Standard | Purpose |

| BRC | Food safety management |

| IFS | Product quality auditing |

| SQF | Consistent safety approach |

| FSSC 22000 | ISO-based global framework |