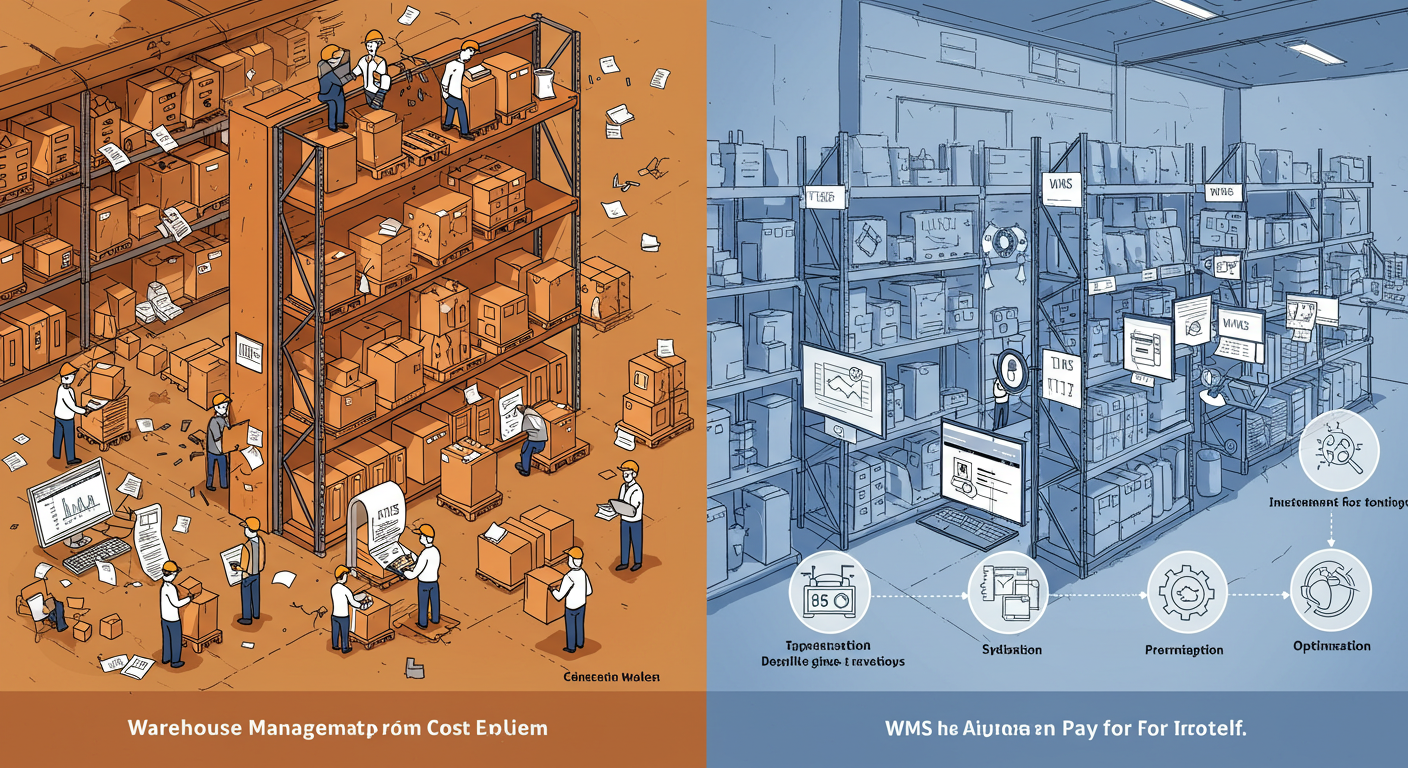

Running a warehouse involves a lot of moving parts. Inventory needs to be tracked, orders need to be fulfilled on time, and everything has to run like clockwork. A good Warehouse Management System (WMS) can make all of this a lot easier. But when it comes to WMS, one question often looms large: How much does it cost?

Before you get too caught up in the numbers, it’s important to know that the cost of a Warehouse Management System isn’t just an expense—it’s an investment. Choosing the right WMS, like WareGo, can transform your warehouse operations in ways that more than make up for the initial cost. So, let’s break this down and take a look at what goes into the cost of a WMS and why it’s worth every penny.

What is a Warehouse Management System?

At its simplest, a Warehouse Management System (WMS) is software designed to optimize the processes inside your warehouse. This includes everything from tracking inventory to managing order fulfillment. A good WMS helps you keep tabs on what’s in stock, where items are located, and ensures that orders get processed accurately and on time.

Think of it as the brain behind your warehouse operations—making sure everything runs smoothly and efficiently. The key benefits of a WMS include real-time inventory tracking, streamlined workflows, reduced errors, and improved customer satisfaction.

But, just like any major investment, it’s important to weigh the costs before jumping in.

What Affects the Cost of a WMS?

The cost of a WMS can vary widely depending on several factors. Here’s what you need to know.

1. Cloud-Based vs. On-Premises

- Cloud-Based WMS: Systems like WareGo are hosted in the cloud, meaning you don’t need to worry about buying hardware or maintaining servers. Instead, you pay for the software on a subscription basis. This makes it a flexible and cost-effective option for businesses that want to avoid hefty upfront costs. Plus, updates and maintenance are handled by the provider, saving you time and money.

- On-Premises WMS: This type of system requires you to buy software licenses, hardware, and often an IT team to manage the system. While it gives you more control over your data, it also comes with higher initial costs. For many businesses, the cloud-based option is the more affordable and scalable solution.

2. Size and Complexity of Your Warehouse

Not all warehouses are created equal, so your system’s cost will depend on how large and complex your operations are. Smaller warehouses with simpler processes can usually get by with a more basic WMS, which will be cheaper. On the other hand, larger warehouses or those with more complex needs—like multiple locations or high-volume operations—will require a more advanced system.

The size of your team is also a factor. The more people that need access to the system, the more expensive your WMS might be. But don’t worry—the right system will help streamline your processes, making it worth the investment.

3. Customization and Integration

Every business is unique, so some warehouses require a bit more customization. If your WMS needs to integrate with existing software systems like your Enterprise Resource Planning (ERP) system or customer relationship management (CRM) tools, this will add to the cost.

- Standard WMS: A pre-built system with all the basics can be relatively inexpensive.

- Custom WMS: A customized system, built to meet your specific needs, can be pricier but will offer more flexibility.

If you’re thinking about WareGo, it offers an easy-to-integrate solution, meaning you won’t have to worry about a long, costly setup process.

4. Support and Maintenance

Once your WMS is up and running, you’ll need ongoing support to keep it running smoothly. This might include software updates, troubleshooting, and training for your team. Some systems, like WareGo, include ongoing support in the subscription cost, while others may charge extra for these services.

Make sure to factor in these support and maintenance costs when assessing the overall cost of the WMS. While they may seem like an added expense, they are crucial for ensuring your system continues to operate effectively.

5. Training Costs

It’s one thing to implement a WMS, but it’s another to make sure your team knows how to use it. If you choose a more complex system, you’ll need to account for training costs. Even with simpler systems, some level of training will be necessary to ensure your staff can get the most out of the software.

While training costs are an added expense, they help ensure that your team is using the system to its full potential. A well-trained team can avoid costly mistakes and help speed up the implementation process.

Why the Right WMS Pays for Itself

Now that we’ve looked at the factors influencing the cost of a WMS, let’s talk about why this investment is worth it. Here’s how the right system can pay for itself in the long run.

1. Increased Efficiency

One of the main reasons businesses invest in a WMS is to improve efficiency. A good WMS can automate a lot of manual tasks, like order picking, inventory tracking, and stock reordering. This means fewer errors and faster processing times. With WareGo, you can expect streamlined workflows and real-time visibility into your inventory, helping you get more done in less time.

2. Fewer Mistakes and Less Waste

Manual processes are prone to errors. Maybe an item gets placed in the wrong spot or an order is sent out incomplete. These mistakes add up—and they’re costly. With a WMS, you reduce the likelihood of these errors. The system can automatically update inventory counts, prevent stockouts, and ensure that the right items are picked for the right orders. This means fewer returns, fewer unhappy customers, and fewer costly mistakes.

3. Better Space Utilization

Warehouse space is valuable, and maximizing it is key to keeping costs down. A WMS helps you organize your warehouse more efficiently, using intelligent algorithms to determine the best locations for items. By optimizing your space, you can store more products without needing to expand your facility, saving you money on additional space costs.

4. Improved Customer Satisfaction

At the end of the day, happy customers are what drive your business. A WMS like WareGo helps you meet customer expectations by ensuring that orders are fulfilled accurately and shipped quickly. Better inventory management also means fewer stockouts, so your customers can always find what they need. Fast, accurate shipments lead to repeat business and improved customer loyalty, which directly impacts your bottom line.

5. Scalability for Growth

As your business grows, your warehouse needs will change. A good WMS grows with you, making it easier to manage more inventory, process more orders, and scale your operations. This means that your initial investment in a WMS will continue to deliver value as your business expands, helping you stay competitive and efficient.

The Bottom Line: Is the Cost of a WMS Worth It?

The warehouse management system cost might seem high at first glance, but when you factor in the improvements in efficiency, accuracy, and customer satisfaction, it’s clear that the right WMS is worth the investment.

A system like WareGo can help streamline your operations, reduce errors, and provide the insights you need to make smarter decisions. Whether you’re running a small warehouse or a large operation, the right WMS can help you save money in the long run.

In the end, the cost of a WMS isn’t just about what you pay upfront—it’s about the long-term value it brings. By improving efficiency, reducing waste, and enhancing customer satisfaction, a WMS pays for itself over time. So, if you’re thinking about investing in a WMS, don’t look at it as an expense—see it as a way to grow your business, improve your processes, and ultimately, boost your bottom line.